The expert level tester for your motor service

Compact design and a wide range of applications for troubleshooting in windings that are not live are the distinguishing features of MotorAnalyzer2 R2.

15 elaborate tests and test methods are built in, including

surge voltage tests up to 3 kV. Due to its integrated lithium-ion battery, tests can also be performed off-grid without a power connection.

Motor Analyzer 2 R2 is the ultimate ALL-IN-ONE tester for electrical engineering, motor repair, maintenance and servicing.

No other portable tester for this scope of application offers such a wide range of support for fault detection and servicing in motors and generators.

Motor Analyzer 2 Details:

The universal tool.

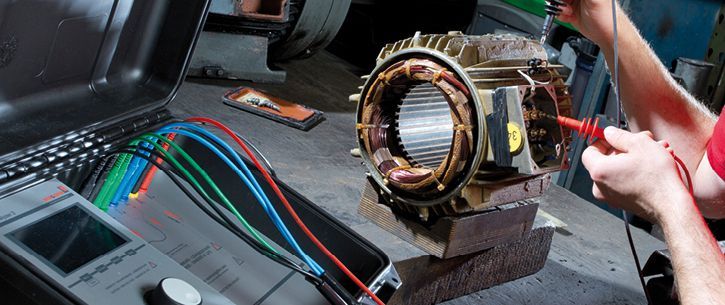

The versatile MotorAnalyzer2 R2 was designed for testing electric motors and windings. It combines 15 different test methods in a single user-friendly and portable device. The combination of test methods, its exceptionally compact design and optional battery mode operation make MotorAnalyzer2 R2 an excellent tool for on-site use – especially in difficult mounting locations.

To check an AC motor, the three winding leads and the motor frame are connected to the tester. For high-precision resistance measurement it is best to use 4-wire measurement. MotorAnalyzer2 R2 automatically starts the surge voltage, resistance, inductance and high-voltage tests one after the other. The internal relay matrix automatically switches the different test methods in sequence to the four measuring points.

In addition to motor testing, MotorAnalyzer2 R2 also assists in adjusting the brush of a DC motor (neutral zone adjustment) and for fault location of the two slots in which the coil with the turn-to-turn fault is located.

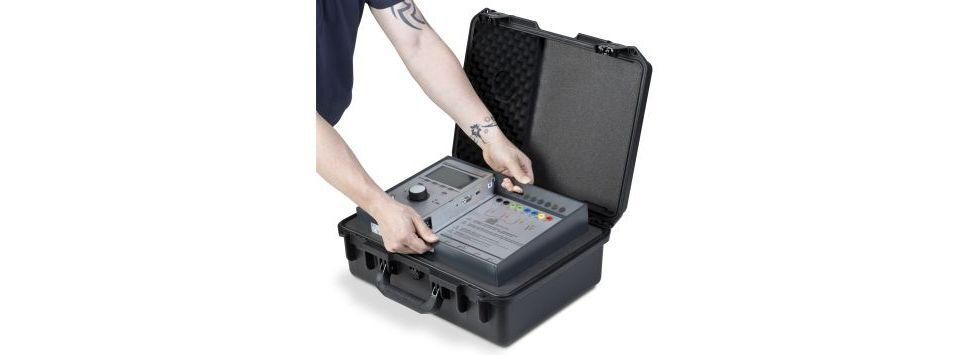

MotorAnalyzer2 R2 is mounted in a very compact, sturdy and waterproof transport case. Next to the control panel you can find a storage compartment for all measuring cables and test probes. At on-site measurements the operator always has all necessary equipment at hand quickly.

Harder mechanical use can optionally be absorbed with a case plus integrated shock absorber concept.

Unrivalled versatility. A class of its own.

universal ALL-IN-ONE tester for

asynchronous motors, induction motors

generators AC, DC

synchronous motors AC, DC

servos

DC motors

brushless DC

coiled armatures and fields

motor brake coil, clutch coil

1-phase motors

1-, 3-phase transformers

…

full motor diagnostics in a few minutes

testing motors up to 700 V nominal current

ideal for

fault detection

fault localization

quality assurance

Ingoing-outgoing inspection of new, defective and repaired windings

trend analysis

predictive maintenance

…

15 test methods

fully automated autotest to check the motor’s “health”

surge voltage up to 3 kV, 100 nF surge capacitance incl. peak to peak testing!

resistance in 4-wire measurement with temperature compensation

insulation resistance up to 6 kV with temperature compensation

high voltage DC up to 6 kV

polarization index PI and DAR up to 6 kV

inductance (L)

RIC-test at squirrel cage rotors (RIC: Rotor Influence Check)

impedance (Z)

capacitance (C) – winding to frame

PE/GB-resistance

adjusting the neutral zone at DC motors

rotary field of stator or motor

use a test probe to locate the slot/the coil in which the winding short circuit is located

4 test connections for 3 phases and the motor frame

built-in multipath automatic switchover with display of the active test method via LEDs

testing without having to reconnect test leads multiple times

test can also be performed directly at the control cabinet via several hundred meters of connecting cables to the motor

automatic testing with automatic pass/no pass-statement

toggle between standard or expert mode

type label information input possible

built-in test result memory for thousands of tests

test results logs

transfer of test results to a PC via USB stick

PC: User-friendly test report printout including your company logo on any Windows printer

PC: User-friendly test report printout as PDF document, ideal for sending test reports via e-mail

Display

color display with easy-to-read graphics

partly enlarged images for better readability from a greater distance

unambiguous measurement values with easy-to-understand physical units

calibration and calibration certificate included

off-grid battery operation for up to 8 hours of continuous use

sturdy transport case containing all measuring accessories

optionally with [SHOCK PROTECTION] case

small, lightweight, carry-on size for air travel

Technical specifications overview

Autotest

automatic stator- and motor-tests

fully-automatic fault analysis

connect once – then test everything

automatic switching between the test methods

automatic switching between the up to 4 test leads

Surge voltage

up to 3,000 V

automatic and manual surge voltage tests

surge voltage tests specifically designed for stators

surge voltage tests specifically designed for fully assembled motors

automatic stepwise test voltage increase (peak to peak)

1, 2 and 3-phase

graphical visualization of the surge wave

automatic analysis

Resistance

1, 2 and 3-phase

imbalance analysis – scattering between phases

high-precision 4-wire measurement (4W)

ambient/winding temperature compensation

Inductance

1-, 2- and 3-phase

imbalance analysis – scattering between phases

high-precision 4-wire measurement

RIC-Test (Rotor Influence Check) – squirrel cage rotor test

3-phase

measurement of the angle-dependent asymmetry of the squirrel-cage rotor

Impedance

1-, 2- and 3-phase

imbalance analysis – scattering between phases

high-precision 4-wire measurement (4W)

High voltage DC

0 – 6,000 V DC

manually adjustable

programmable (automatic)

step voltage test

Polarization index & DAR

0 – 6,000 V DC

PI-test

DAR-test

automated measurement

Insulation resistance

0 – 6,000 V DC

up to 500 GΩ (1 TΩ)

e.g. with 500 V in accordance with VDE 0701

ambient/winding temperature compensation

PE/GB-resistance

in accordance with VDE 0701

Capacitance

Capacitance between the entire coils and the motor frame

Neutral Zone adjustment for DC motors

bar chart indicating the deviation from the neutral zone

acoustic indication of the misalignment from the neutral zone by means of a signal tone

This allows you to optimally concentrate on adjustment during the measurement – and you do not have to look at the display.

Rotary Field of the stator

stator – rotary field measurement with a rotary field probe

Sense of rotation of the motor

motor – sense of rotation measurement

Locating the slots with Turn-to-Turn fault

Locating the slot in which the turn-to-turn fault is located by means of a test probe

for stators and wound rotors

bar chart indicating the slot to slot deviation

modulated acoustic notification if test results are outside the specified limits

This allows you to optimally concentrate on the positioning of the measuring probe above the slot during the measurement – and you do not have to look at the display.

Power Supply

built-in rechargeable battery

wide range of line voltages: 90 – 250 V, 47 – 63 Hz

key switch for activation

This means that, if necessary, the MotorAnalyzer can only be used by authorized persons.

NAICS Codes

334515,

54138, 811219,811310

Cage Code

4P2J9

Duns Number

79-119-1351

Contact Info:

MOTOR DIAGNOSTIC SYSTEMS, INC.

inside.sales@mdsusa.net

Sales: +1 (970) 461-1348

or +1(877) 461-1348

Fax: +1 (866) 223-0800

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

All Rights Reserved | Motor Diagnostic Systems Powered by The Way Consulting