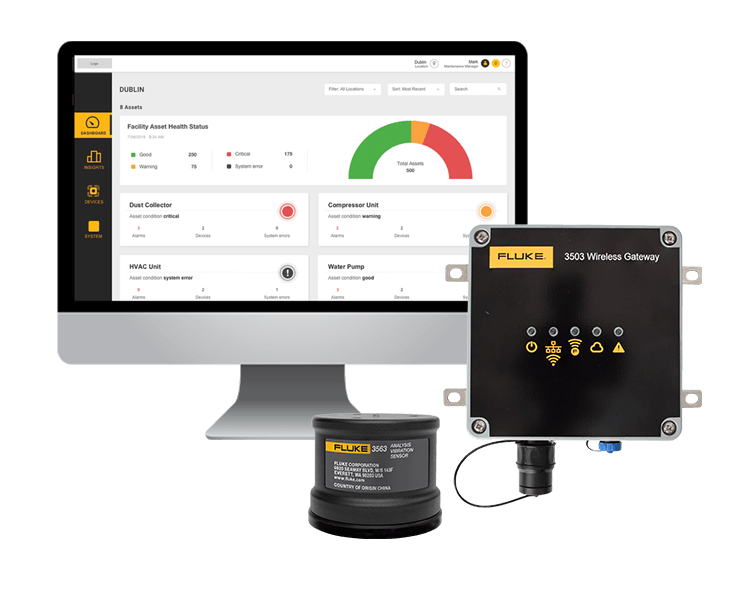

Fluke 3563 Analysis Vibration Sensor

Wireless Vibration Sensor and Gateway

With the new 3563 Analysis Vibration Sensor, you get high-value wireless vibration-monitoring technology for a broad array of machine types.

- Extend machine health and peak performance

- Leverage high-powered software analytics

- Determine the fault causing a problem and the cause of that fault

high-frequency piezoelectric sensor and insightful software analytics

The Fluke 3563 combines a high-frequency piezoelectric sensor and insightful software analytics, enabling maintenance teams to regularly monitor and analyze vibration readings for a facility’s production-critical assets. Its smart battery management lets maintenance pros determine the data transmission rate and adapt and extend the sensor battery’s life while still getting the data required.

The sensor’s LIVE-Asset™ Portal software application includes customizable frequency band measurements, automatically generated thresholds based on asset details, trend visualization, and frequency identification graphs. These views enable users to determine which fault is causing a problem to an asset and the cause of the fault. With this analysis, users can evaluate critical next-step actions to take. The result is extended peak operating performance and more efficient maintenance team use – delivering increased business value from maintenance operations.

Combined with setup and vibration training services, the Fluke 3563 can be implemented seamlessly into existing plant operations while yielding the efficiency benefits promised by condition monitoring and practical leverage of the IIoT. The Fluke 3563 Analysis Vibration Sensor system is a solution that seamlessly combines three parts: hardware, software, and service. The one-on-one setup process includes personalized assistance from Fluke Reliability experts, ensuring successful configuration, commissioning, and installation.

Essential hardware features

- The sensor captures the following measurements:

- Vibration measurements that include RMS and peak-to-peak (supported measurement quantities are velocity and acceleration)

- Time waveform

- Temperature

- The measurements are sent to the gateway by a short-range wireless technology standard

- A battery-operated triaxial sensor that leverages two MEMS sensors and a high-frequency, high-resolution piezoelectric sensor

- The two MEMS sensors are used to measure low-frequency vibrations in the X and Y orthogonal axes

- The piezoelectric sensor measures both low- and high-frequency vibrations in the Z-axis, which is the main sensing axis

- Dual network capabilities: Wi-Fi and Ethernet

- A unique smart battery-management capability that allows for a user-determined data transmission rate, maximizing battery life

Key LIVE-Asset™ Portal software features

- Dashboard: Displays the overall condition of assets from associated devices, with summary-level data visible by location.

- Visualized measurements: Monitor assets at a glance by visualizing the following measurement data:

- Overall velocity and acceleration

- Temperature

- Acceleration and velocity bands

- Bearing Severity Overalls

- Vibration trending graphs: Graphing supports a user’s analysis and provides access to measured parameters, including trend charts.

- Thresholds and Event Notifications

- Leverage customizable and auto-generated thresholds based on asset details

- Warning notifications are received via email and/or through the LIVE-Asset™ Portal.

- Overview of Asset Event History: Users can add/edit asset information and review the history of monitored changes and associate device information in LIVE-Asset Portal.

Services

Our Expertise as a Service offering bolsters maintenance teams with assistance and training when they need it. Teams can take advantage of these services to launch condition monitoring programs that position them for a future of IIoT:

- Remote and onsite setup services: including asset-to-sensor analysis, network and schedule configurations, commissioning, installation, post-onboarding report, and more

- Vibration training: including core principles, how to read vibration data, and how to take data-based actions

- Custom installation and vibration training packages

NAICS Codes

334515,

54138, 811219,811310

Cage Code

4P2J9

Duns Number

79-119-1351

Contact Info:

MOTOR DIAGNOSTIC SYSTEMS, INC.

inside.sales@mdsusa.net

Sales: +1 (970) 461-1348

or +1(877) 461-1348

Fax: +1 (866) 223-0800

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

All Rights Reserved | Motor Diagnostic Systems Powered by The Way Consulting