AEMC Power Quality Analyzer PowerPad® III Model 8435

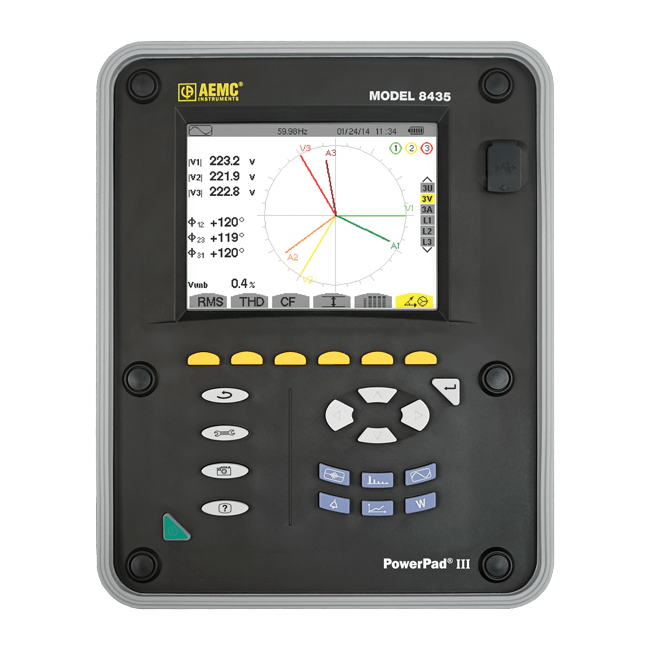

The PowerPad® III Model 8435 is a three-phase power quality analyzer

- Measurement of TRMS voltages up to 1000Vrms AD/DC for two-, three-, four- or five-wire systems

- Measurement of TRMS currents up to 6500Arms (sensor dependent)

- Direct measurement of neutral current and voltage

- Frequency measurement (40 to 70Hz systems)

- Records and displays trend data as fast as once per second for one month up to 25 variables

- Captures up to 210 transient occurrences on all V and A inputs

- Measures harmonics (referenced to the fundamental or RMS value) for voltage, current or power up to the 50th harmonic

- Recording, time stamping and characterization of disturbance (swells, sages and interruptions, exceedance of power and harmonic thresholds)

- 2GB SD Card for Trend Recording memory; Alarm, Snapshot, Transient and Inrush stored in internal flash memory

- Measures energy VAh, VARh & Wh

- 65µs/sample transient recording

- FREE DataView® software is included for configuring real-time display and report generation

The PowerPad® III Model 8435 is a three-phase power quality analyzer...

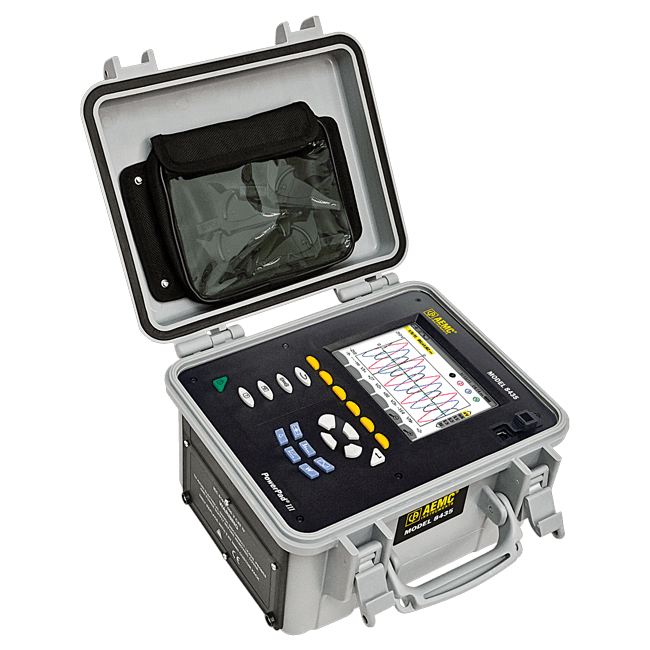

...that is easy-to-use, compact and shock resistant. It enables technicians and engineers to measure and carry out diagnostics and power quality work on one-, two- or three- phase networks. Four voltage and four current inputs are provided. It is IP67 waterproof rated when recording with cover closed.

The Model 8435 has 2GB of memory available for storing trend data. Additional internal memory is conveniently partitioned to let you store alarms, transients, inrush and snapshot data synchronized or independent of each other. The user can store up to 50 screen snapshots, up to 210 captured transients that contain four cycles for each active input, and 10,000 alarm events from up to 40 different parameters. Trend data can also be recorded for days, weeks or even months. Inrush current can also be captured and stored.

Applications:

- Verification of power distribution circuits

- Pole mounting

- In-plant troubleshooting of power distribution panels and individual machinery

- Monitor pad mount transformers and phase unbalances

- Determine harmonic problems originating from source or load

- Determine transformer K-Factor

- Energy metering (kVAh, VARh, kWh)

NAICS Codes

334515,

54138, 811219,811310

Cage Code

4P2J9

Duns Number

79-119-1351

Contact Info:

MOTOR DIAGNOSTIC SYSTEMS, INC.

inside.sales@mdsusa.net

Sales: +1 (970) 461-1348

or +1(877) 461-1348

Fax: +1 (866) 223-0800

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

All Rights Reserved | Motor Diagnostic Systems Powered by The Way Consulting