AEMC Thermal Imaging IR Camera Model 1950

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Provides ease with professional reports, fast start up, focus free operation and simple to use tools. Get quality measurements in seconds!

The AEMC’s Thermal Imaging IR Camera Model 1950 is equipped with infrared thermography detection technology that is used in sectors of industry as diverse as electrical maintenance, metallurgy and steel making, petroleum, automation, natural gas exploration, transportation and in other professions such as fire-fighting and surveillance. Infrared thermal imaging provides a real-time non-contact inspection method that does not require you to shut off power, shut down the equipment or interrupt production. It can diagnose latent malfunctions in advance and anticipate their occurrence and prevent production problems. The Model1950 is a powerful cost effective tool for analyzing electrical maintenance issues. It has features typically found in cameras two to three times its price.

Key Features and Functions:

Provides a wide 20° 120° field of view with an IF0V spatial resolution of 4.4mrad.

This allows you to quickly inspect a large area in real-time, and capture a high level

of thermal information in a single thermogram. Focus on a 0.08611 (2.2mm) object from 9.8' (3m) away. Capture desired measurements from a distance with the camera's 75:1 ratio.

Focus free quality

Provides crisp, clear thermal and digital images without the need for adjustments.

Accurate temperature measurement over the full range.

From -4 to 482°F (-20 to 250°C) with a stability of 80mk at 86°F (30°C).

Audio narration can be recorded with thermograms.

You can describe the circumstances of each image, providing additional text and description to be stored with each image.

Automatic non-uniformity temperature correction.

Compensates for any internal drift to improve accuracy.

Measurement data can also be stored with each thermogram.

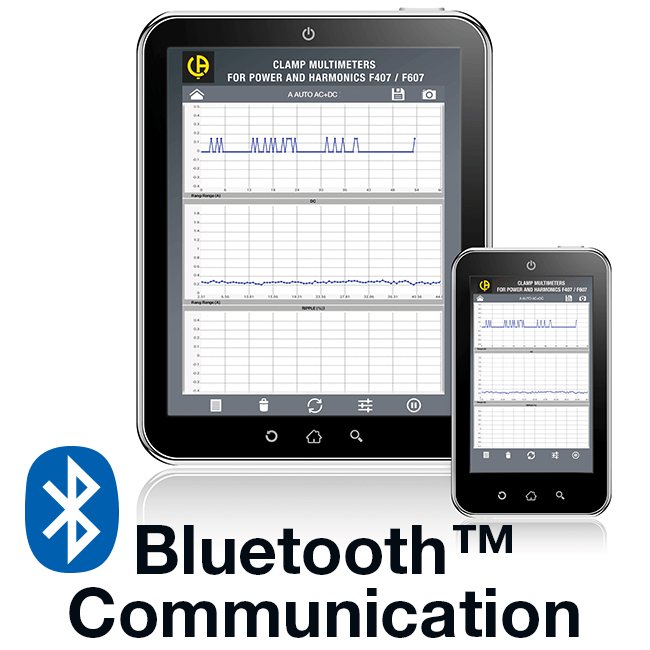

The Model 1950 can wirelessly connect via 8/bluetooth to a compatible AEMC® clamp-on meter or multimeter, enabling you to combine electrical measurements to the imaging data.

Offers broad range of operational capabilities.

Locating the cold and hot spots in the image, measuring the temperature of a selected point in the image, displaying the temperature profile of a line in the image, displaying points at the same temperature in the image, and freezing the colors representing the temperatures.

CAmReport software.

Included for downloading stored files from the instrument to a computer for further processing,analysis, and report generation.

This camera is built to last.

Its rugged design survives accidentally dropping on any of its surfaces from as high as 6'.

Exceptionally long 13 hour battery life.

Ensures no loss of test time during a typical work day.

Applications:

- Measure efficiency, find areas for potential savings

- Track sub-billing occupants for energy costs

- Assign energy costs to departments or operations within a department

- Track peak demand periods and find opportunities for surcharge reductions

- Determine present capacity and circumvent unnecessary electrical expansion costs

- Monitor stray voltages and neutral current

- Verify the reliability and operation of electrical machinery

- Improve response time to solve power related problems

- Track energy availability and reliability of supply

- Reduce field service time at sub-stations

- Baseline studies for system upgrades in high-rise and office buildings

- Remote configurations, monitoring and event loading

NAICS Codes

334515,

54138, 811219,811310

Cage Code

4P2J9

Duns Number

79-119-1351

Contact Info:

MOTOR DIAGNOSTIC SYSTEMS, INC.

inside.sales@mdsusa.net

Sales: +1 (970) 461-1348

or +1(877) 461-1348

Fax: +1 (866) 223-0800

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

All Rights Reserved | Motor Diagnostic Systems Powered by The Way Consulting